Technology

- CelluXtreme®’s unique technology platform is a game changer.

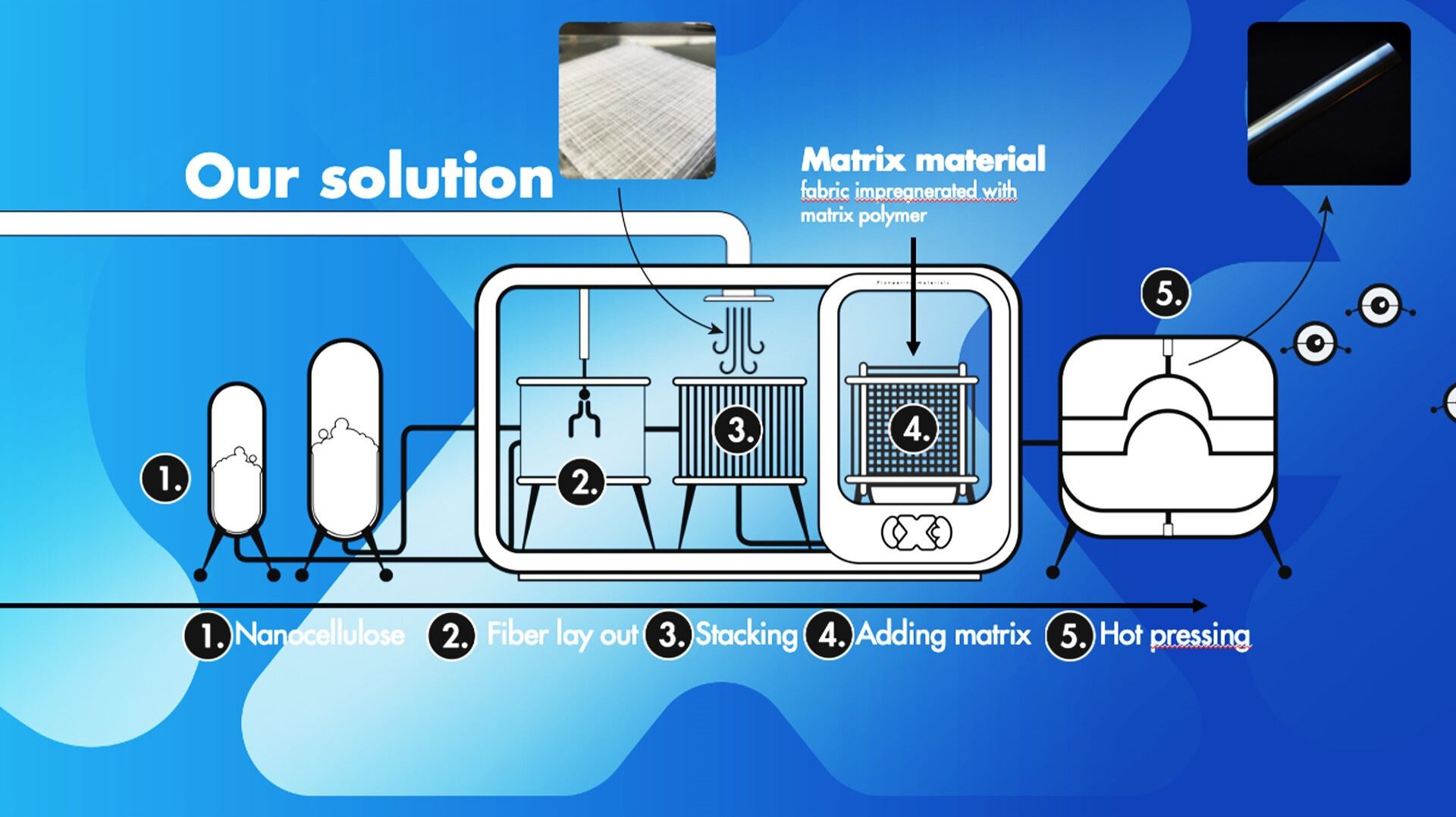

- The patented key process – based on flow-focusing, makes it possible to spin strong filaments from 100% cellulose using a water-based process based on green chemistry principles, being all-over low in emissions.

- These filaments are spun into complex two- and three-dimensional fabrics in a single step, enabling product-centric and flexible manufacturing.

- The fabrics are impregnated with a polymer and formed into strong, stiff and thin lightweight composite materials with unique properties.

FIBRE KOLFIBER

”Kolfiber” refers to carbon fibre, a remarkable material renowned for its exceptional strength, low weight, and versatility. In scientific terms, carbon fiber is a composite material composed primarily of carbon atoms bonded together in a crystal alignment. These carbon atoms are ar- ranged in a specific molecular structure, typical- ly in a graphite-like sheet structure, which gives carbon fiber its unique properties.

The manufacturing process of carbon fiber in- volves several steps. Initially, precursor materi- als such as polyacrylonitrile (PAN), pitch, or rayon fibers are subjected to processes like ox- idation and carbonization in high-temperature environments, typically without oxygen, to remove non-carbon elements and create a high carbon content material. This process results in the formation of long, thin carbon filaments.

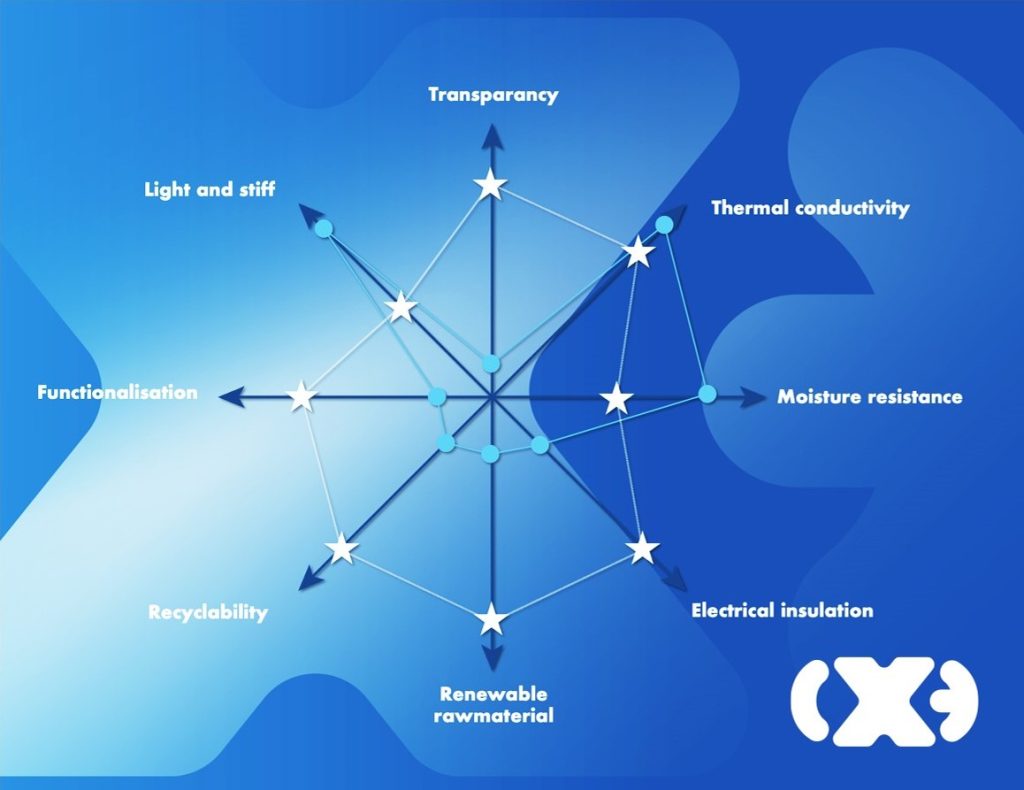

CX3-fibre is performance talents, opening property combinations without limitations

- Sustainable and high performing

- Thermal conducting and electrical insulation

- Light and transparent

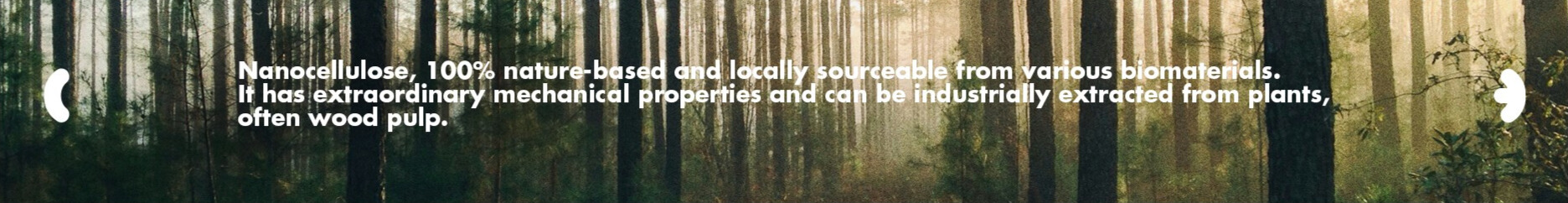

- Renewable and controlled quality: Fabric from natures bases material, nanocellulose, removes the variability elsewise encountered with natural fibres.