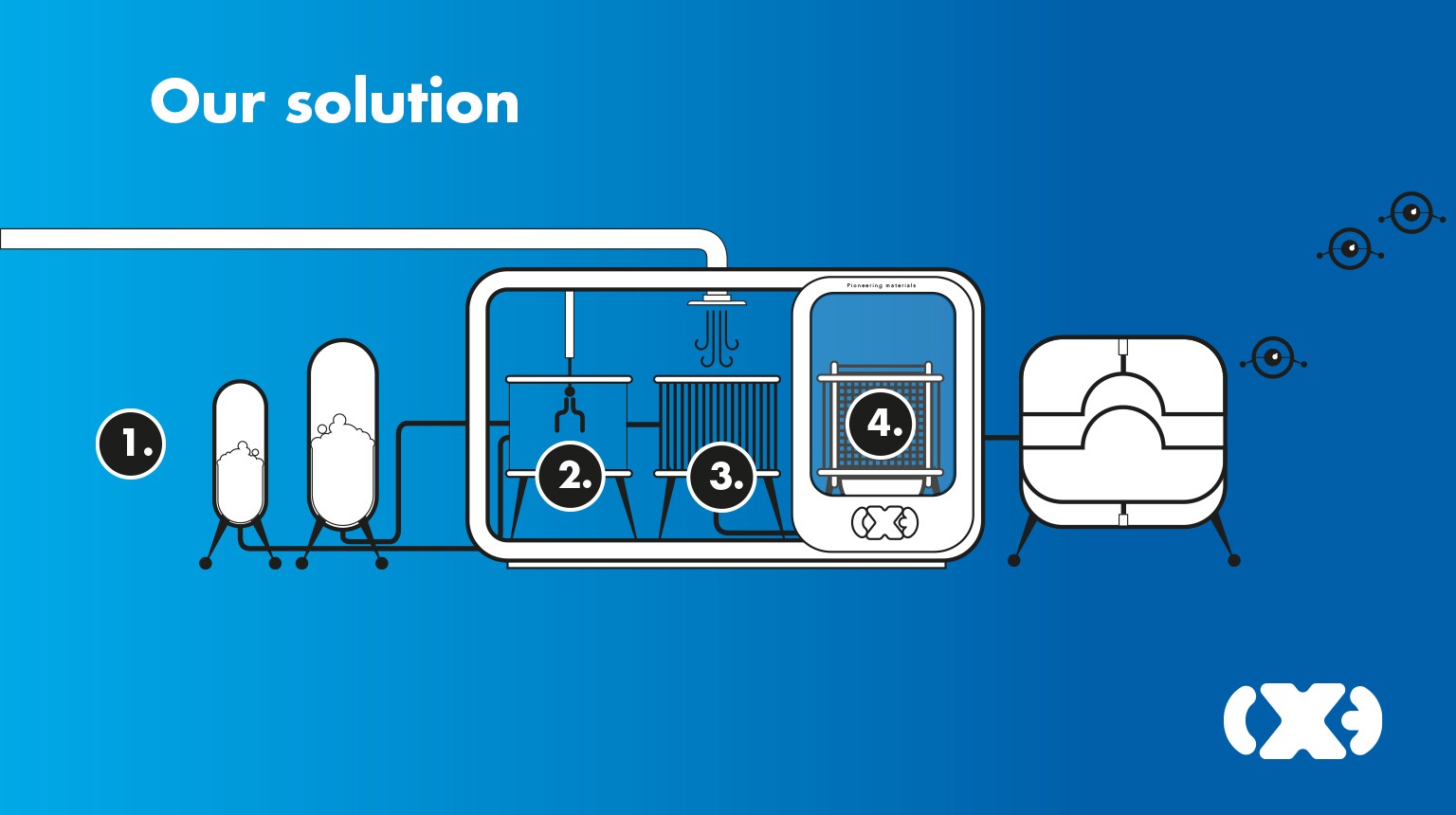

our solution

WE BELIEVE THAT NEW MATERIAL TECHNOLOGY IS AN ESSENTIAL PART OF SUSTAINABLE GROWTH.

the technology

- CelluXtreme’s unique technology platform is a game changer.

The patented spinning process – based on flow focusing – makes it possible to spin strong and stiff fibres from 100% cellulose using a water-based process, that is all-over low in emissions. - The fibres are spun into complex two and three-dimensional fabrics in a single step, enabling customer-centric and flexible manufacturing.

- The fabrics are impregnated with a polymer matrix and formed into thin, lightweight composite materials with unique properties.

Nanocellulose is 100% nature-based and locally sourceable from various biomaterials.

It has extraordinary mechanical properties and can be industrially extracted from plants, often wood pulp.

Fibre layout, a water-based process for continuously spinning nanocellulose into solidifying gel threads via flow-focusing and extrusion of the formed fabric.

Drying, at ambient and moderate temperatures of the extruded fibre. Only water vapouris emitted by our water-based process, allowing drying into the atmosphere.

Matrix selection as by customer choice of the composite properties, enabling individualisation and design freedom.

fibre and fabric

- Lightweighting

- Electrical insulation

- Thermal conductivity

Transparency

- Functionalisation

- Biobased raw material source

- Recyclability

CelluXtreme fibre is performance talents, opening property combinations without limitations

- Sustainable and high-performing

- Thermal conductivity and electrical insulation

- Light and transparent

- Renewable and controlled quality:

- Fabric from natural nanocellulose removes the variability encountered otherwise by natural fibres.

The fibre surface shows high adhesion to different matrix systems, enabling strong bonding.

Composite materials can be formed by established processes into customer-demanded shapes.

CelluXtremes Green Leap Composites, offer sustainable alternatives for advancing global industries.

SCIENTIFIC HISTORY

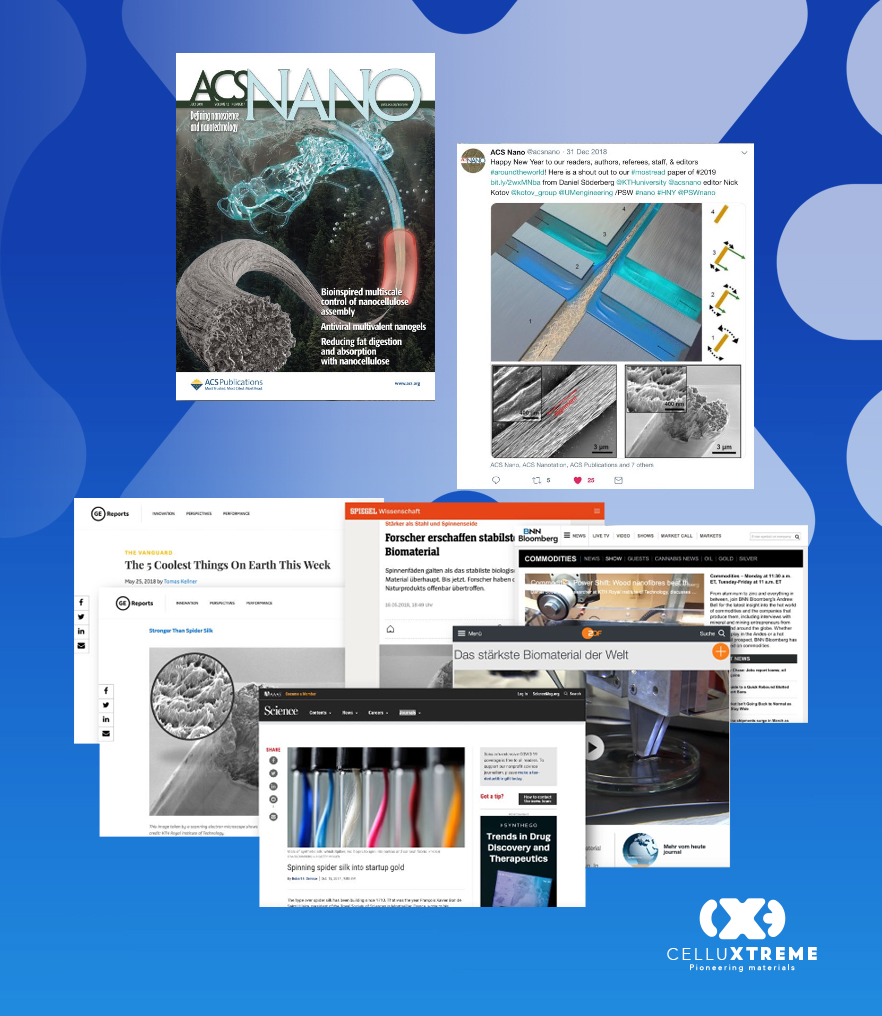

The CelluXtreme technology results from over ten years of research conducted at KTH and RISE, particularly within the Wallenberg Wood Science Center. In 2018, the strongest biobased fibre ever was produced, with results published in ACS Nano. This article was recognised as the most-read ACS Nano publication of the year.

2009 Wallenberg Wood Science Center was started at KTH and Chalmers through funding provided by Knut and Alice Wallenberg Foundation

2012 As a result of the scientific collaboration between experts in multiphase flows and fibre and colloid science, a new technique is invented, and a patent application is sent in.

2014 The use of the technique is published in Nature Communications, and an example of functionalisation for electrical conductivity is presented in ACS Nano, the number one scientific journal in the field of nanotechnology. The results get worldwide attention.

2017 After further process development the properties are improved and it is shown how the spun fibres can be functionalised using spider silk to obtain increased toughness and bioactivity, the results are published in ACS Nano. Again the results get a wider attention since it successfully shows a route for making use if the unique properties of silk in an engineering material that has the potential for industrial scaleup.

2018 By extending our knowledge on nanocellulose preparation and optimal process conditions, it is possible to spin even stiffer and stronger fibres, including results that show that the fibres can regain stiffness after plastic deformation under mechanical load, results that were published in ACS Nano, and with an even stronger impact, which also resulted in appearances in media, e.g. BNN Bloomberg, P.M. Wissen on Servus TV in Austria and ZDF Heute in Germany.

2021 Continued research on optimal process conditions and means of controlling nanoscale assembly resulted in an invitation to elucidate the challenges as a review article in Advanced Materials.

Scientific foundation of the spinning process – flow-focusing

Prof. Daniel Söderberg, founder of CelluXtremeand inventor of the patented key process based on flow focusing, explains the physics principles and flow-structure-control which enabled today’s scaled production. Treesearch seminar, September 20, 2021.